Johnson outboard wiring diagrams provide essential guidance for understanding electrical systems, troubleshooting, and performing safe repairs. These schematics are crucial for technicians and DIY enthusiasts alike, offering clear, detailed representations of wiring connections and components specific to Johnson outboard motors.

1.1 Importance of Schematic Diagrams for Outboard Motors

Schematic diagrams are indispensable for understanding and working with Johnson outboard motors. They provide a clear visual representation of electrical systems, enabling technicians and DIY enthusiasts to diagnose issues efficiently. These diagrams detail wiring connections, color codes, and component locations, ensuring accurate repairs and maintenance. By following a schematic, users can identify faults, such as faulty connections or damaged harnesses, and address them safely. This prevents costly mistakes and potential safety hazards. Additionally, schematics are tailored to specific models, making them essential for troubleshooting and ensuring compatibility with original equipment. They also serve as a reference for installing upgrades or aftermarket components, guaranteeing proper integration with existing systems. Overall, schematic diagrams are vital for maintaining the performance, reliability, and safety of Johnson outboard motors.

1.2 Overview of Johnson Outboard Motor Models

Johnson outboard motors are renowned for their durability and performance, catering to a wide range of boating needs. Their model lineup includes various horsepower options, from compact 2HP units to powerful 85HP engines, ensuring versatility for different vessel sizes and applications. Specific models, such as the 85HP (e.g., 85852, 85853) and 40HP (e.g., 40802, 40803), are detailed in service manuals that provide comprehensive maintenance and repair guidance. These manuals often feature high-resolution diagrams and step-by-step instructions, covering systems like fuel, ignition, and electrical components. Whether for routine maintenance or complex overhauls, Johnson’s extensive model range and supporting documentation make them a reliable choice for both recreational and professional use, ensuring optimal performance and longevity of their outboard motors.

Key Components of Johnson Outboard Wiring Diagrams

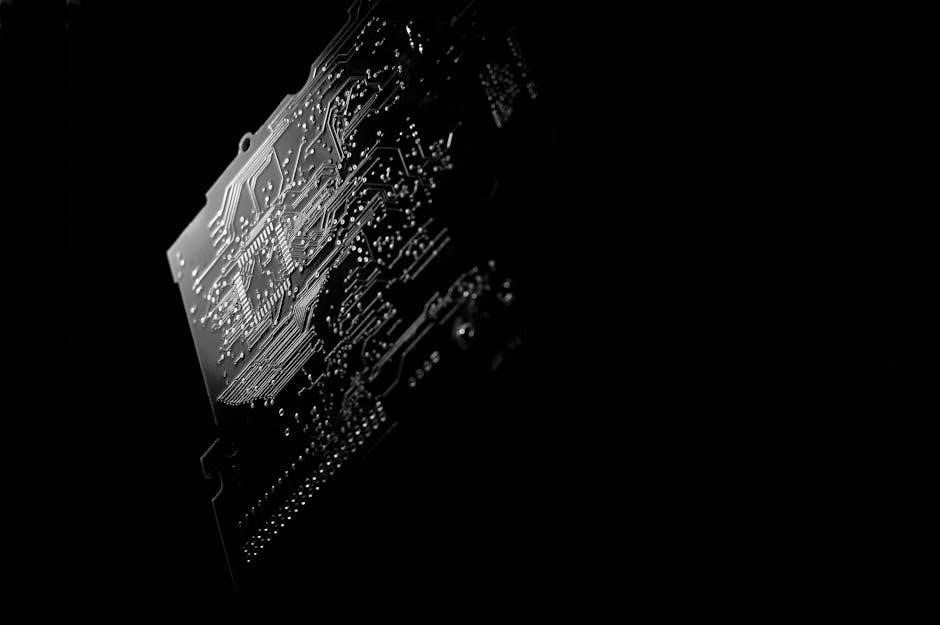

Johnson outboard wiring diagrams highlight essential components like the wiring harness, connectors, electrical systems, and sensors. These elements ensure proper connectivity and function, aiding in diagnostics and repairs.

2.1 Understanding the Wiring Harness and Connectors

The wiring harness is the backbone of Johnson outboard electrical systems, connecting components like sensors, ignition, and controls. It consists of insulated wires bundled together for protection and organization. Connectors are critical for secure links between components, ensuring reliable signal transmission. Proper identification and maintenance of these parts are essential for system functionality and longevity;

2.2 Identifying Electrical Systems and Sensors

Johnson outboard wiring diagrams detail the electrical systems and sensors crucial for engine operation. Key components include ignition systems, fuel injection sensors, and control modules. Sensors like RPM, temperature, and fuel level monitors ensure optimal performance; These systems are interconnected, with wiring harnesses linking sensors to the engine control unit (ECU) for precise data processing. Accurate identification of these elements is vital for diagnostics and repairs, as malfunctioning sensors can disrupt engine functionality. Understanding their roles and connections helps technicians pinpoint issues efficiently, ensuring reliable operation and preventing potential breakdowns. Proper maintenance of these electrical systems is essential for longevity and peak performance of Johnson outboard motors. Always refer to the wiring diagram for specific model details to avoid errors during servicing or repairs. This ensures compliance with manufacturer specifications and safety standards. Regular inspection of sensors and connections can prevent costly repairs and extend the life of the outboard motor. By familiarizing yourself with the electrical layout, you can address issues promptly and maintain your motor in top condition.

How to Read and Interpret Wiring Diagrams

Understanding symbols, color codes, and model-specific details is crucial for interpreting Johnson outboard wiring diagrams. These elements ensure accurate troubleshooting and repairs, aligning with your motor’s exact specifications.

3.1 Deciphering Symbols and Color Codes

Deciphering symbols and color codes in Johnson outboard wiring diagrams is essential for accurate repairs. Symbols represent components like batteries, solenoids, and sensors, while colors indicate wire functions. Red often signifies positive battery connections, while black may denote ground or negative lines. Understanding these codes ensures proper identification of circuits and connections, reducing the risk of electrical errors. Referencing the legend provided in the diagram or manual is crucial for clarity. Correct interpretation prevents miswiring, which could lead to system malfunctions or safety hazards. Properly identifying each symbol and color ensures efficient and safe troubleshooting, aligning with the specific requirements of your Johnson outboard model.

3.2 Matching Diagrams to Specific Johnson Outboard Models

Matching wiring diagrams to specific Johnson outboard models is crucial for accurate repairs and maintenance. Each model, such as the 40HP or 85HP, has unique electrical configurations, and using the correct diagram ensures compatibility. Identify your outboard’s model number and year to select the appropriate schematic. Official Johnson service manuals and PDF guides often include model-specific wiring diagrams, detailing components like ignition systems and sensors. Online repositories and forums also provide downloadable diagrams tailored to particular models. Verify the diagram matches your outboard’s specifications, as variations exist between remote control and tiller models. This step ensures precise troubleshooting and avoids costly errors. Always cross-reference your diagram with the outboard’s serial number and manual for accuracy.

Common Wiring Issues and Troubleshooting

Common wiring issues include corrosion, damaged insulation, and loose connections, leading to power loss or component failure. Use diagrams to identify and repair faults systematically.

4.1 Diagnosing Faulty Electrical Connections

Diagnosing faulty electrical connections in Johnson outboard wiring requires a systematic approach. Start by consulting the wiring diagram to identify potential problem areas. Inspect connectors and terminals for signs of corrosion or damage. Use a multimeter to test for continuity and voltage drops across suspect connections. Common issues include loose wires, oxidized terminals, and damaged insulation, which can disrupt power flow. Perform a visual inspection of the wiring harness, paying attention to areas exposed to moisture or heat. Check for blown fuses or tripped circuit breakers, as these can indicate overloaded circuits or short faults. By methodically tracing the wiring diagram and testing each connection, technicians can pinpoint the root cause of electrical malfunctions and ensure reliable system operation.

4.2 Repairing Damaged Wiring Harnesses

Repairing damaged wiring harnesses in Johnson outboards requires precision and adherence to the wiring diagram. Begin by disconnecting the battery to prevent accidental power surges. Inspect the harness for frayed wires, corrosion, or melted insulation, using the diagram to trace damaged sections. Clean or replace corroded connectors, and splice wires using heat-shrink tubing or soldering for a secure connection. Ensure all repairs align with the original wiring configuration to maintain system integrity. After completing the repair, reconnect the battery and test the electrical systems to confirm proper functionality. Regular maintenance and protective measures, such as applying dielectric grease to connectors, can prevent future damage and ensure reliable performance of the outboard motor.

Safety Guidelines for Working with Outboard Wiring

Always disconnect the battery before starting repairs to prevent electrical shocks or short circuits. Use proper tools and follow the wiring diagram to ensure safe and accurate work.

5;1 General Safety Precautions

When working with Johnson outboard wiring, always disconnect the battery to prevent accidental starts or electrical shocks. Ensure the motor is in neutral gear and apply the emergency kill switch. Wear protective gear, including gloves and safety glasses, to safeguard against potential hazards. Avoid working near open flames or sparks, as fuel vapors can ignite. Keep a fire extinguisher nearby and ensure good ventilation. Never attempt repairs while the motor is running or hot. Follow the wiring diagram carefully to avoid misconnections that could lead to system malfunctions. Properly insulate tools to prevent short circuits. If unsure, consult a professional technician to ensure safety and compliance with manufacturer guidelines.

5.2 Avoiding Common Mistakes in Wiring Repairs

Common mistakes in wiring repairs include incorrect wire connections, which can damage electrical components or cause system failures. Always refer to the Johnson outboard wiring diagram to ensure accuracy. Overlooking corrosion or wear on connectors can lead to poor conductivity and intermittent issues. Avoid using incompatible materials, as they may degrade over time. Never splice wires without proper insulation, as this can result in short circuits. Ensure all connections are secure and tightened to the specified torque to prevent vibration-related failures. Misidentifying wire colors or symbols in the diagram can lead to critical errors. Double-checking each connection before powering up the system is essential to avoid costly repairs and safety hazards.

Resources for Johnson Outboard Wiring Diagrams

Official Johnson service manuals and PDF guides provide detailed wiring diagrams for specific models. Online repositories and forums offer downloadable schematics, ensuring easy access for repairs and maintenance.

6.1 Official Johnson Service Manuals and PDF Guides

Official Johnson service manuals and PDF guides are the most reliable sources for detailed wiring diagrams and repair information. These manuals cover a wide range of Johnson outboard models, including 40HP, 85HP, and Ski-Twin engines. They provide comprehensive maintenance and repair procedures, high-resolution diagrams, and step-by-step instructions. The manuals are designed for both technicians and DIY enthusiasts, ensuring accurate troubleshooting and repair. Many PDF guides are available for free or purchase online, offering easy access to wiring schematics, electrical system overviews, and model-specific instructions. These resources are essential for understanding and working with Johnson outboard wiring systems effectively.

6.2 Online Repositories and Forums for Wiring Diagrams

Online repositories and forums are valuable resources for accessing Johnson outboard wiring diagrams. Websites like Boats.net and specialized forums offer a wide range of wiring schematics for various Johnson models, including 2-stroke engines. These platforms often provide free PDF downloads, ensuring easy access to detailed diagrams. Many repositories cater to both professionals and DIY enthusiasts, offering step-by-step instructions and troubleshooting tips. Forums also allow users to share experiences and solutions, creating a community-driven support system. While diagrams are generally accurate, variations may exist between models or control types, so verification is recommended before starting repairs. These online resources are indispensable for maintaining and repairing Johnson outboard motors efficiently.