Manual transaxles integrate transmission, axle, and differential. Early designs featured sliding-mesh systems, evolving to constant-mesh with 5-6 speeds for modern vehicles.

What is a Transaxle?

A transaxle represents a compact automotive component, cleverly combining the functions of a traditional transmission, axle, and differential into a single, unified assembly. This integrated design is particularly prevalent in front-wheel drive vehicles, where it efficiently delivers power to the driving wheels. The transaxle case, typically constructed from aluminum, provides robust housing and support for all internal parts.

Within a manual transaxle, the input shaft receives power from the engine, while the output shaft transmits it to the axles. Crucially, the transaxle differential allows the axles to rotate at varying speeds, essential for navigating turns smoothly. Understanding this core functionality is key to appreciating the ingenuity of this automotive system.

Manual vs. Automatic Transaxles: A Comparison

The fundamental difference between manual and automatic transaxles lies in how gear changes are executed. Manual transaxles demand direct driver intervention, requiring clutch operation and deliberate gear selection for optimal control and a more engaging driving experience. This often translates to lower costs and increased fuel efficiency.

Conversely, automatic transaxles prioritize ease and convenience, handling gear shifts autonomously. They are favored by drivers seeking a relaxed, stress-free ride, especially in congested urban environments. However, automatics traditionally sacrifice some control and can be less fuel-efficient. Modern advancements are blurring these lines, with both types incorporating features from the other, enhancing overall performance.

Core Components of a Manual Transaxle

A manual transaxle comprises a case, input/output shafts, and a differential. These key elements work together to transfer power and manage speed effectively.

Transaxle Case: Housing and Support

The transaxle case, typically constructed from aluminum, serves as the foundational housing for the entire assembly. Its primary function is to securely enclose and provide robust support for all the internal components of the manual transaxle. This protective shell safeguards the delicate gears, shafts, and differential mechanisms from external contaminants like road debris, moisture, and physical impacts.

Beyond mere protection, the case’s design contributes significantly to the structural integrity of the transaxle. It’s engineered to withstand the substantial stresses generated during power transmission and shifting operations. Mounting points on the case facilitate secure attachment to the vehicle’s chassis, ensuring proper alignment and minimizing vibrations. The case also incorporates provisions for sealing elements, preventing lubricant leakage and maintaining optimal operating conditions. Essentially, the transaxle case is the backbone of the entire system.

Input Shaft: Receiving Power

The input shaft is the crucial component responsible for initially receiving rotational power from the engine’s flywheel and clutch assembly. It acts as the primary conduit, transferring the engine’s torque into the transaxle’s internal gear train. This shaft is meticulously engineered to withstand significant torsional stresses generated by the engine’s output.

Typically, the input shaft features splines that engage directly with the clutch disc, enabling a secure and efficient power transfer. Bearings support the shaft, minimizing friction and ensuring smooth rotation. Its design often incorporates a pilot bearing to center the input shaft within the crankshaft, maintaining proper alignment. The input shaft’s durability and precision are paramount for reliable transaxle operation, directly impacting the vehicle’s performance and drivability.

Output Shaft: Delivering Power

The output shaft represents the final stage in the manual transaxle’s power delivery system. Receiving torque from the gear train and differential, it’s responsible for transmitting rotational force to the drive axles, ultimately propelling the vehicle. This shaft is robustly constructed to handle the substantial torque loads generated during acceleration and cruising.

Splines on the output shaft connect directly to the constant-velocity joints of the drive axles, ensuring smooth and efficient power transfer even as the axles articulate with suspension movement. Bearings support the shaft, minimizing friction and ensuring consistent rotation. The output shaft’s design is critical for maintaining vehicle stability and responsiveness, directly influencing driving dynamics and overall performance.

Transaxle Differential: Torque Transfer and Speed Variation

The transaxle differential is a crucial component, expertly transferring gearbox torque to the driving axles while simultaneously permitting the axles to rotate at differing speeds – essential for cornering. This ingenious mechanism allows outer wheels to travel a greater distance than inner wheels during a turn, preventing wheel slippage and maintaining traction.

Typically employing a set of pinion and side gears, the differential distributes power proportionally to each wheel. Its design ensures smooth and controlled power delivery, enhancing vehicle stability and handling. The differential’s robust construction withstands significant stresses, contributing to the transaxle’s overall durability and reliability.

Gear Train Mechanics

Gear ratios significantly impact vehicle speed and torque. Synchronizers ensure smooth gear changes, while shift forks and selector rods actuate those changes precisely.

Gear Ratios and Their Impact

Gear ratios are fundamental to a manual transaxle’s operation, dictating the relationship between engine speed and wheel rotation. Lower gear ratios provide increased torque, ideal for acceleration and climbing hills, but limit top speed. Conversely, higher gear ratios offer reduced torque but enable higher speeds with improved fuel efficiency on level ground.

The selection of appropriate gear ratios is crucial for optimizing vehicle performance based on intended use. A wider range of ratios allows for greater versatility, adapting to diverse driving conditions. Understanding how gear ratios influence acceleration, speed, and fuel economy is essential for maximizing the potential of a manual transaxle system. These ratios directly affect the mechanical advantage within the drivetrain.

Synchronizers: Smooth Gear Changes

Synchronizers are vital components within a manual transaxle, enabling smooth and effortless gear changes. Their primary function is to equalize the rotational speeds of the gear being engaged and the main shaft before the clutch fully engages. This prevents grinding and jarring during shifts, protecting the gears from damage and enhancing driver comfort.

Without synchronizers, shifting would be a rough and potentially destructive process. They utilize friction to match speeds, employing a cone-shaped surface that contacts the gear. Modern synchronizers often incorporate materials designed to maximize friction and durability. Proper synchronizer function is critical for a pleasant and reliable driving experience with a manual transmission.

Shift Forks and Selector Rods: Actuating Gear Changes

Shift forks and selector rods are the mechanical intermediaries that translate the driver’s gear selection into actual gear engagement within the manual transaxle; The selector rod, connected to the gear shift lever, moves laterally to engage with the appropriate shift fork. The shift fork then slides the selected gear along the main shaft, initiating the gear change process.

Precise movement and alignment are crucial for smooth operation. Worn or damaged shift forks or selector rods can lead to imprecise shifting, difficulty selecting gears, or even complete failure. These components work in concert with the synchronizers to ensure a seamless transition between gears, providing the driver with control and responsiveness.

Clutch System Integration

The clutch—disc, pressure plate, and flywheel—disconnects engine power. Master and slave cylinders, linked by linkage, translate pedal action to disengage the drivetrain.

Clutch Disc, Pressure Plate, and Flywheel

The clutch disc, a friction material-faced circular plate, directly connects to the transmission’s input shaft. Sandwiched between the flywheel and the pressure plate, it transmits engine power when engaged. The flywheel, bolted to the engine’s crankshaft, provides a smooth surface for clutch engagement and stores rotational energy.

The pressure plate, spring-loaded, clamps the clutch disc against the flywheel, creating friction and transferring power. When the clutch pedal is pressed, this clamping force is released, disengaging the engine from the transmission. Proper function of these three components is crucial for smooth gear changes and overall drivetrain efficiency. Wear on any component diminishes performance, leading to slippage or difficulty shifting.

Clutch Master and Slave Cylinders

The clutch master cylinder, activated by the clutch pedal, pressurizes hydraulic fluid when depressed. This pressurized fluid travels through a clutch line to the slave cylinder, located near the transaxle. The slave cylinder then uses this hydraulic pressure to operate the clutch fork, disengaging the clutch.

This hydraulic system amplifies the force applied to the pedal, making clutch operation easier. Proper functioning of both cylinders is vital for smooth and reliable clutch engagement and disengagement. Leaks or internal failures within either cylinder can result in a soft pedal, difficulty shifting, or complete clutch failure, requiring immediate attention and repair.

Clutch Linkage and Pedal Operation

The clutch pedal initiates the disengagement process, connecting to a linkage system – either cable or hydraulic – that transmits force to the clutch. In cable systems, a cable directly pulls on the clutch fork. Hydraulic systems, utilizing a master and slave cylinder, amplify force via fluid pressure.

Proper pedal feel and travel are crucial. Adjustments ensure complete clutch disengagement without excessive effort. Worn or damaged linkage components can cause incomplete disengagement, leading to grinding gears. Regular inspection and lubrication of the linkage are essential for smooth operation and prolonged component life, ensuring a responsive and enjoyable driving experience.

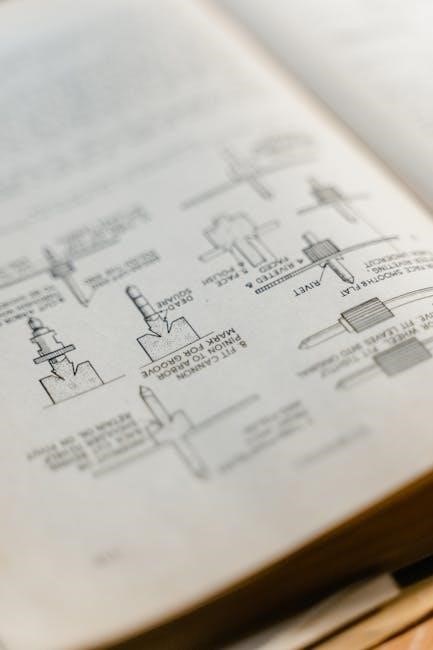

Detailed Diagram Breakdown

A manual transaxle diagram reveals key components: the case, input/output shafts, differential, and gear train, illustrating how power is transferred efficiently.

Identifying Key Components in a Diagram

When examining a manual transaxle diagram, several crucial components become readily identifiable. The transaxle case, typically an aluminum housing, encloses and protects the internal workings. You’ll clearly see the input shaft, responsible for receiving power from the engine’s clutch. Conversely, the output shaft delivers the power to the driving axles.

A central element is the transaxle differential, vital for transferring torque and allowing wheels to rotate at differing speeds during turns. The gear train, a complex arrangement of gears, dictates the various gear ratios. Furthermore, diagrams highlight shift forks and selector rods, which actuate gear changes, and the synchronizers, ensuring smooth transitions between gears. Recognizing these parts is fundamental to understanding the transaxle’s operation.

Understanding Gear Arrangement in a Diagram

A manual transaxle diagram reveals a carefully orchestrated gear arrangement. Different sized gears mesh to create varying gear ratios, impacting speed and torque. Lower gears provide more torque for acceleration, while higher gears prioritize fuel efficiency at cruising speeds. The diagram illustrates how power flows from the input shaft, through the selected gear pair, and ultimately to the output shaft.

Observe how gears are positioned on the shafts; this dictates the ratio. Constant-mesh designs ensure gears are always engaged, with synchronizers facilitating smooth shifts. The arrangement also showcases how the differential integrates, allowing for independent wheel speeds. Analyzing this layout clarifies how the transaxle converts engine power into usable motion.

Analyzing Differential Mechanism in a Diagram

A manual transaxle diagram clearly depicts the differential’s crucial role. This mechanism transfers gearbox torque to the driving axles, enabling wheels to rotate at different speeds during turns. Pinion gears connect to side gears, allowing for this speed variation. Without a differential, wheel scrub and drivetrain stress would occur when cornering.

The diagram highlights how the differential housing encloses these components. Understanding its operation is key to grasping transaxle functionality. It’s vital for smooth, controlled handling. The differential’s design ensures power is distributed effectively, maximizing traction and minimizing tire wear. Analyzing this section reveals a sophisticated system within the transaxle assembly.

Common Manual Transaxle Types

Manual transaxle diagrams showcase Front-Wheel Drive (FWD) and Rear-Wheel Drive (RWD) configurations, differing in axle and differential placement for power delivery.

Front-Wheel Drive (FWD) Manual Transaxles

FWD manual transaxles, as depicted in detailed diagrams, consolidate the transmission, differential, and drive axles into a single unit. This compact design efficiently delivers power to the front wheels. A typical diagram reveals the input shaft receiving power from the engine’s clutch, transferring it through the gear train to the differential.

The differential then splits the torque and allows for varying wheel speeds during turns, directing power to the side axles connected to the front wheels. Diagrams clearly illustrate the arrangement of gears, synchronizers, and shift mechanisms within the transaxle case. Understanding these diagrams is crucial for diagnosing and repairing FWD systems, highlighting the integrated nature of power transmission in these vehicles.

Rear-Wheel Drive (RWD) Manual Transaxles

RWD manual transaxles, as shown in illustrative diagrams, differ from FWD configurations by transmitting power to the rear wheels. A detailed diagram showcases the input shaft receiving engine power, channeling it through the gear train and differential. However, unlike FWD systems, the output of the differential connects to a separate driveshaft.

This driveshaft then extends to the rear axle, delivering torque to the rear wheels. Diagrams emphasize the distinct separation of the transmission/differential unit from the driven wheels. Analyzing these diagrams reveals the arrangement of components within the transaxle case and the subsequent power flow to the rear. Understanding this layout is vital for effective RWD system maintenance and repair.

Troubleshooting Common Issues

A manual transaxle diagram aids in diagnosing grinding gears, clutch slippage, or noisy operation by visually pinpointing component locations and potential failure points.

Grinding Gears: Causes and Solutions

A manual transaxle diagram is invaluable when troubleshooting grinding gears; This issue often stems from incomplete clutch disengagement, worn synchronizers, or low transaxle fluid. The diagram helps visualize the gear train and identify potential points of friction or damage.

If the clutch isn’t fully releasing, the input shaft remains partially engaged, causing gear clash during shifts. Worn synchronizers, responsible for matching gear speeds, fail to smoothly engage, leading to grinding. Inspecting these components using the diagram as a reference is crucial.

Low fluid reduces lubrication, exacerbating wear. Solutions include clutch adjustment or replacement, synchronizer replacement, and a complete fluid change. The diagram assists in locating these parts for efficient repair.

Clutch Slippage: Diagnosis and Repair

A manual transaxle diagram is essential for diagnosing clutch slippage. This occurs when the clutch disc doesn’t firmly engage the flywheel, resulting in engine revving without proportional vehicle acceleration. The diagram illustrates the clutch assembly – disc, pressure plate, and flywheel – aiding visual inspection.

Common causes include a worn clutch disc, a weakened pressure plate, or oil contamination. Examining the diagram helps understand how these components interact. Oil reduces friction, while wear diminishes clamping force.

Diagnosis involves checking for glazing or wear on the disc. Repair typically requires replacing the entire clutch assembly – disc, pressure plate, and potentially the flywheel if damaged. The diagram guides proper reassembly.

Noisy Operation: Identifying the Source

A manual transaxle diagram proves invaluable when pinpointing the source of unusual noises. Whining, grinding, or clunking sounds often indicate internal issues. The diagram details gear arrangements, shafts, and the differential, helping isolate the problematic area.

Noises can stem from worn gear teeth, failing bearings, or a damaged differential. The diagram clarifies how these components mesh and rotate, revealing potential friction points. Low fluid levels can also contribute to noise.

Careful listening, combined with the diagram’s visual guide, assists in differentiating between gear noise, bearing rumble, and differential whine. Repair may involve replacing gears, bearings, or addressing fluid leaks, guided by the diagram’s component layout.

Maintenance and Servicing

A manual transaxle diagram aids fluid changes, wear item inspection, and proper lubrication. Understanding component locations ensures thorough servicing and extends transaxle life.

Fluid Changes: Type and Frequency

Regular fluid changes are crucial for manual transaxle longevity. A manual transaxle diagram helps locate the drain and fill plugs for efficient servicing. Typically, manufacturers recommend using a specific gear oil type – often a GL-4 or GL-5 rated lubricant – detailed in the vehicle’s owner’s manual;

Change intervals vary based on driving conditions. Normal driving usually necessitates a fluid change every 30,000 to 60,000 miles. However, severe conditions, like frequent towing or aggressive driving, may require more frequent changes, potentially every 15,000 to 30,000 miles.

Consulting a diagram ensures correct fluid level after refilling, preventing damage. Ignoring fluid maintenance leads to increased wear, noise, and eventual failure of the transaxle’s internal components.

Inspection of Wear Items

Periodic inspection of wear items is vital for manual transaxle health. A detailed manual transaxle diagram aids in locating key components for assessment. Regularly check the clutch disc, pressure plate, and throw-out bearing for signs of wear or damage during clutch service. Inspect synchronizers for smooth gear engagement; grinding noises indicate potential issues.

Examine shift forks and selector rods for bending or excessive play. Look for leaks around the transaxle case, indicating potential seal failures. A visual inspection of the gear teeth, using the diagram as a reference, can reveal pitting or chipping.

Addressing wear promptly prevents further damage and costly repairs, ensuring reliable operation.

Proper Lubrication Techniques

Correct lubrication is crucial for manual transaxle longevity. Referencing a manual transaxle diagram helps identify fill and drain plugs. Use only the manufacturer-recommended fluid type – typically a GL-4 gear oil – to ensure compatibility with internal components. Avoid overfilling, as this can cause pressure buildup and leaks.

When changing fluid, thoroughly clean the drain plug to prevent debris from re-entering the system. Ensure the fill plug is accessible before draining the old fluid! Proper lubrication minimizes friction, reduces wear, and dissipates heat, extending the transaxle’s lifespan.

Regular fluid changes, guided by the diagram for access points, are essential preventative maintenance.

Evolution of Manual Transaxle Design

Early manual transaxles used sliding-mesh systems; modern designs employ constant-mesh with increased gear ratios, as illustrated in a detailed diagram.

Early Sliding-Mesh Transmissions

Sliding-mesh manual transmissions represent the foundational stage in transaxle development. These early systems, predating the 1950s, operated by physically sliding gears along the shaft to engage different ratios. A diagram reveals how this engagement occurred directly, lacking the synchronizers found in later designs.

This direct engagement meant drivers needed precise timing and skill to match engine speed to the gear, preventing grinding. Typically, these transmissions offered a limited number of forward gears – often three – impacting overall vehicle performance. While simple in concept, the diagram illustrates a relatively complex arrangement of gears and forks. The transaxle case, visible in a schematic, housed these components, providing structural support and lubrication. Understanding this early design is crucial for appreciating the advancements in modern manual transaxles.

Modern Constant-Mesh Transmissions

Constant-mesh transmissions, appearing from the 1950s onward, revolutionized manual transaxle design. Unlike their predecessors, gears remain constantly meshed, improving efficiency and smoothness. A diagram showcases how synchronizers facilitate gear changes, matching speeds before engagement to eliminate grinding.

This diagram reveals a more refined internal layout compared to sliding-mesh systems. The transaxle case now supports a more intricate arrangement of gears, synchronizers, shift forks, and selector rods. Modern designs commonly feature 5 or 6 forward speeds, enhancing fuel economy and performance. The differential, clearly visible in a schematic, efficiently transfers torque. Understanding the diagram highlights the sophisticated engineering behind these reliable and efficient transaxles, offering a smoother driving experience.

The Rise of 5-Speed and 6-Speed Manuals

The evolution from 3-speed to 5 and 6-speed manual transaxles significantly impacted vehicle performance and efficiency. A detailed diagram illustrates the increased complexity, showcasing additional gear sets within the transaxle case; These extra gears allow for closer ratios, optimizing engine speed for various driving conditions.

Examining a diagram reveals how these advancements necessitate more sophisticated synchronizer mechanisms and shift linkages. The differential remains a crucial component, efficiently distributing power. Modern manual transaxles, as depicted in schematics, prioritize both fuel economy and driver engagement. The diagram demonstrates the intricate interplay of components, resulting in a more refined and versatile driving experience, offering greater control and responsiveness.